The Benefits of Experience

Precision 3 Axis CNC Surface Grinding Machine 515CNC

Main Machine Features:

1. Spindle motor: Use ABB brand from Sweden.

2. Spindle bearing: Use NSK brand P4 grade precision ball bearing from Japan.

3. Cross and vertical screw: Use P5 grade precision ball screw.

4. Main electrical components: Use SIEMENS brand.

5. Main hydraulic components: Use brand from TAIWAN.

6. Hydraulic motor components: Use brand of WEG which from Brazil.

7. Long distance control valve: Use Germany import brand HAWE, it can achieve

precision location and control table move speed in the button panel.

8. Servo motor (Y and Z axes) components: Use SIEMENS brand.

9. CNC control system: Use SIEMENS 808D.

Main Description:

-3 axes ganged CNC surface grinding machine. It is a advanced machine which

have high

performance, wide processing range and high efficiency advantages, mainly

used in black

metals, nonferrous metals and some of nonmetal material parts grinding

process. It can

rough and fine grinding surface, slot, arc surface and complexity hook face

processing.

-This machine have high load-bearing, high precision, high stiffness, long life

time, high shock resistance and unfailing performance and many other

advantages.

-Full enclosed splash guard design. It can well isolate dust and machining

spray which

produced by grinding processing. Automatically recycling lubrication system.

It can recycle reclamation to achieve environmental, cost saving and other

advantages.

-Constituted by machine bed, table, saddle, column, head, feeding device,

electrical system, operate cabinet, hydraulic system, full enclosed splash

guard and other parts.

Machine guide way:

Machine guide way use " V " type +flat type. The moving guide way stuck a

layer"TURCITE-B", we called it plastics sticking guide way. It can achieve

wear-resisting and increase life time of the guide way. And the flat guide way

have grinding and scraping process.

Lubrication system:

Automatically recycling lubrication system. It can supply lubricate oil for all

of the guide way.

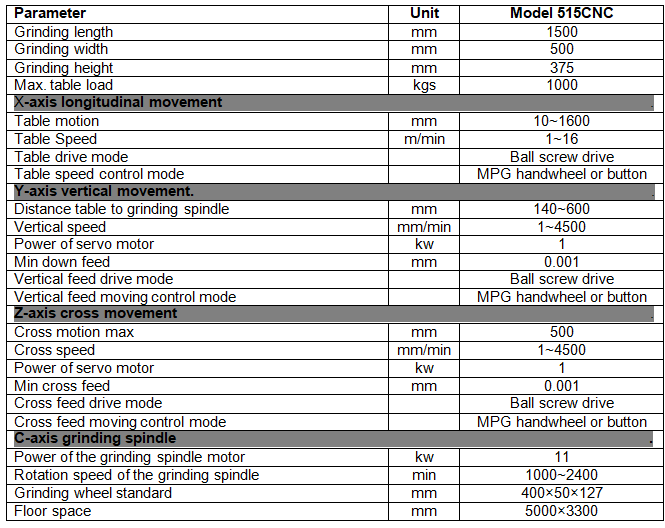

Main Specifications: