The Benefits of Experience

SURFACE MILLING MACHINE

Automatic Downfeed CNC Touch Screen Milling Machine

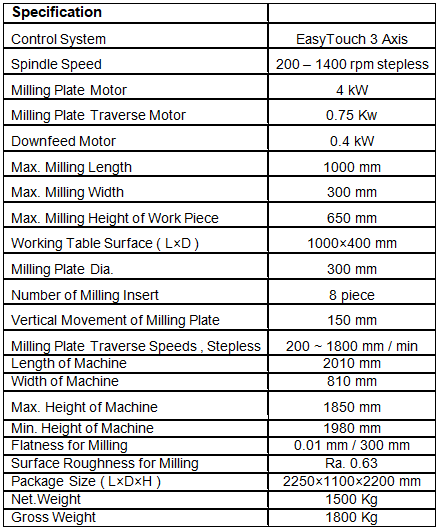

It is Mech-Electrical highly integrated machine uses touch key and screen display. The milling plate longitudinal movement by servo motor, the spindle vertical movement and rotation controlled by servo motor, three axis linkage control, high precision, high efficiency. This machine has a nice looking, stability, and supermatic, easy to use interface of EasyTouch control system, you can achieve the effect of finishing at RA1.6, flatness can reach to 0.01mm/300mm , same as the grinding.

It is suitable for middle size, small size cylinder head, cylinder block and other Industrial parts required high-precision, high finish.

1.This machine is control by CNC touch screen. The operation contact surface, Simple and easy to get started. It can do automatic feed, automatic retraction after complete all program, also have memory processing trajectory.

2.Main spindle speed and feeding rate is stepless speed change. Suitable for different kinds of processing materials. Total piece of eight cutter folder, you can choose freely to improve processing efficiency.

3.The main spindle use NSK P4 level tapered roller bearing and cylindrical roller bearing to ensure that the spindle has good accuracy and rigidity.

4.Spindle sleeve is chrome plated and ground, with a shining and rust-proof surface, and improve the full rigidity of spindle.

5.Transmission parts: Taiwan ABBA Ball screw Accuracy class C7.

6.Main spindle is derived by servo motor, to ensure a constant output torque at various speeds, so that the processing is more stable, efficient cutting, the work piece surface much more finish better.

7.This machine use head move structure, Has a small footprint, can be processed large volume of work piece, while the low table position, is conducive to the work piece clamping, etc.

8.High flatness, best bright finish, the milling that replaces normal milling, and without the cooling box. Operation is faster, more convenient, work environment is more clean.

Standard equipment:

- Setup blocks

- Milling Head ø300 with 2 Inserts

Extra equipment:

- Milling Head ø300 with 8 Inserts

- Tool Holder for round milling Inserts

- PCD Round Insert for Aluminum

- CBN Round Insert for Cast Iron

- Tool Holder for Triangular Insert

- CBN Triangular insert

- V-block setup fixture

- Setup fixture for Cylinder Head