The Benefits of Experience

Front load Spray Washing Machine

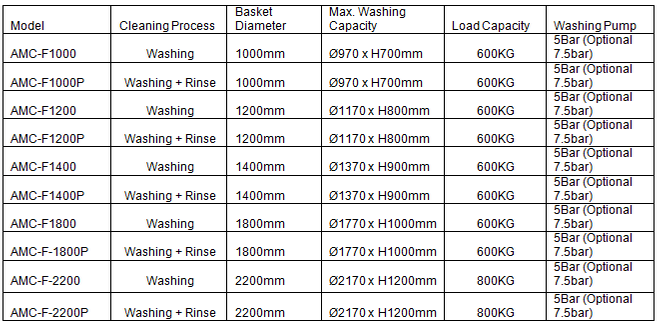

Front Loading Spray Washer

These series washers are multi-stage and single chamber designed. Instead of several separate tanks, which take up valuable floor space and incur costly labor and transport charges, cleaning can now be carried out in one machine with a multi process system. In this machine you can either pre-clean, de-carbonize, wash, degrease, phosphate, rinse, drying, rust inhibit components and so on.

CLEANING PRINCIPLE

Small and medium parts to be washed are placed on the turntable of the washer. When washing, the spray nozzles will create a uniform, multi-direction and heated cleaning solution with medium or high-pressure to quickly and evenly clean the parts. Precise nozzle placement ensures effective and reliable cleaning every time with 360° coverage.

APPLICATIONS

It can be used for medium sized to large sized metal, plastics, ceramics parts for prewashing, inter-operational washing, or final washing, with the possibility of anti-corrosive protection to removes oil, grease, chips, mud, production slag of the surface of parts.

TYPICAL APPLICATIONS:

- Machinery Industry

- Repair and Maintenance Industry

- Automotive, Railway, Ship, Aerospace Industry

- General Engineering Industry

- Precision Metal Industry

- Surface treatment & Processing Industry

- Medical Industry

- Printing Industry

FEATURES

STANDARD:

- Allows for washing parts with different geometry and the material they were

made

- Durable materials: stainless steel chamber, spray pipes, nozzles, pump and

valves

- Motorized and heavy-duty stainless- steel component basket

- Stainless steel spray bar arrangement

- Accurate spraying nozzle arrangement ensures 360° coverage without blind

area for excellent cleaning result

- Pneumatic door with safety lock device

- PLC & HMI control system to set different the cleaning parameters and

operate it easily

- Efficient heating and temperature control system with over temperature

protection device

- Low fluid level sensor will alarm in ultra-low liquid level

- The cleaning liquid can be recycled by circulation & filtration system

- The circulation & filtration system is designed with pressure sensor, which

will remind user to

change the filter elements in time

- Steam extraction fan

- The basket can be used to load different types of part and depending on their

characteristics they may be placed directly onto the basket or onto special

tools or devices

- Safe and ergonomic working environment

OPTIONAL EXTRAS:

- Rinse stage: re-circulating and non-recirculating

- Drying stage: heated and non-heated air blow

- Loading trolley for ergonomically moving heavier loads

- Removable basket gives more possibilities for material handling in production

- Pump upgrades - higher pressure, higher flowrate

- Oil & mist cleaner

- Oil skimmer

- Auto fresh water refill

- Auto detergent dosing unit

- Double skin thermal & sound insulation

- Electric, gas, diesel or steam powered fluid heating

- Depending on the characteristics of the parts to be washed, they may be

loaded onto special supports or devices

Power Supply: 380V, 50Hz, 3PH+N+PE