The Benefits of Experience

ULTRASONIC CLEANING

Professional Industrial Ultrasonic Cleaner

(Multi-direction Ultrasonic Wave)

These series ultrasonic cleaner is professional industrial ultrasonic cleaner to wash different industrial components quickly.

Its transducers arrangement is multi-direction and different from most ultrasonic cleaners in the market, which can achieve more efficient and better cleaning result.

APPLICATIONS

It can be used for different sized metal, plastics, ceramics parts for prewashing, inter-operational washing, or final washing, with the possibility of anti-corrosive protection to removes oil, grease, chips, mud, production slag of the surface of parts.

TYPICAL APPLICATIONS:

- Machinery Industry

- Repair and Maintenance Industry

- Automotive, Railway, Ship, Aerospace Industry

- General Engineering Industry

- Surface treatment & Processing Industry

- Electronic & Semiconductor Industry

- Precision Metal Industry

- Photovoltaic Solar Industry

- Optical & Glassware Industry

- Medical Industry

- Printing Industry

- Food Industry

FEATURES

- Ultrasonic transducers are uniformly mounted in multi directions of cleaning tank for more homogenous, thoroughly and better cleaning efficiency

- The new generation circuit board has stronger power and more stable

- Fast degassing function at the start of the ultrasonic cycle to remove gases

from the solution for maximum ultrasonic cleaning performance

- Auto-tune technology with Sweep and power adjustment for more stable and

better effect

- Original Germany CeramTec piezoelectric ceramic chip, good quality

assurance

- Full-bridge IGBT module, high pressure resistant & high temperate resistance

- Transducers are fixed by stud welding and Switzerland glue to avoid shedding

- Ultrasonic power adjustable linearly

- ASI 304/ASI 316 thickening stainless steel, acid-proof and alkali-resisting

with long work life

- Bigger cleaning tank size for choosing is suitable for different industrial

cleaning requirements

- Cleaning objects are easily taken out by stainless steel cleaning basket

- Cleaning liquid heating function for better cleaning effect

- Double-layer & heat-retaining lid to prevent heat loss and save energy

- Machine lid with gas struts

- Fixed foot and casters with brake, easy to fixation and move

- Equipped with dregs groove to drain dregs easily

- Overflow device

- Components and parts come from world-famous brands

- Special tank size and requirement can be customized

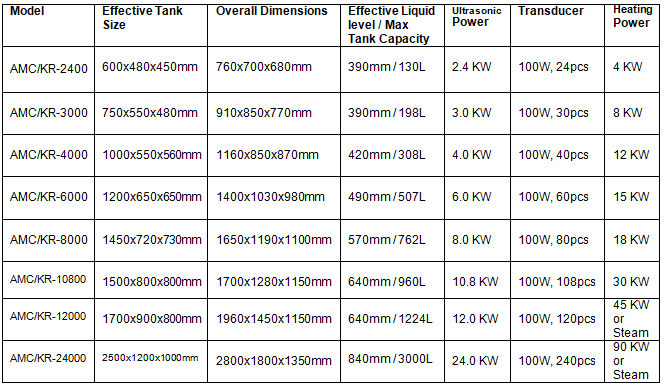

PARAMETERS

- Ultrasonic Wave Direction: All the transducers are regularly fixed in three

sides of cleaning tank.

- Ultrasonic Frequency: 20 / 28 / 40 KHZ, Single

- Ultrasonic Power Adjustable Range: 20% ~ 100%

- Tank Material: ASI 304, thickness 2mm

- Supply Voltage: Ultrasonic generator 220V, 50Hz, 1Ph or 380V, 50Hz,

3Ph+N+PE;

Cleaning tank 380V, 50Hz, 3Ph+N+PE.

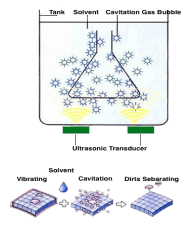

ULTRASONIC CLEANING THEORY

Ultrasonic cleaners generate ultrasonic waves that create millions of tiny bubbles through the process of cavitation. The bubbles gently clean and polish any surface they come in contact with, even inaccessible areas, penetrating every nook and cranny to dislodge trapped dirt and debris. The cleaning objects will be quickly restored to their original luster without expending any effort. The gentle cleaning action ideal for delicate items, too.

Therefore, ultrasonic cleaning method is the best cleaning method than others, because its cleaning efficiency is highest, cleaning result is the best without any trace of physical cleaning and scratches

ULTRASONIC FREQUENCY

Frequency is suggested based on cleaning objects’ material and pollutants in the objects.

Simply to say, higher precision cleaning objects, higher frequency is better.

We can provide three ultrasonic frequency options:

- 20Khz: This frequency is strongest, better for hard and strong metals with

heavy oil and dirty.

- 28Khz: This frequency is stronger, widely used for different metal with heavy

oil and dirty, such as car/motor/truck/vessel/metal parts, to remove oil,

grease, dirt, pastes, etc.

- 40Khz: This frequency is gentle, better for high precision goods and fragile

goods, such as PCB boards, electronic parts, optical elements, glasses and

jewelry, etc.

HOW TO CHOOSE A GOOD ULTRASONIC CLEANER

- Frequency: Choose the suitable ultrasonic frequency according to the above

suggestions.

- Inner size of cleaning tank: It should be bigger than cleaning objects’ size.

- Core element: The core element of an ultrasonic cleaner is ultrasonic

transducer. The quality of ultrasonic transducer influences the service life of

an ultrasonic cleaner greatly.

- Ultrasonic power: For the same inner size of cleaning tank, the ultrasonic

power is bigger, the cleaning effect will be better. For the same ultrasonic

power, the inner size of cleaning tank is smaller, the cleaning effect will be

better.