The Benefits of Experience

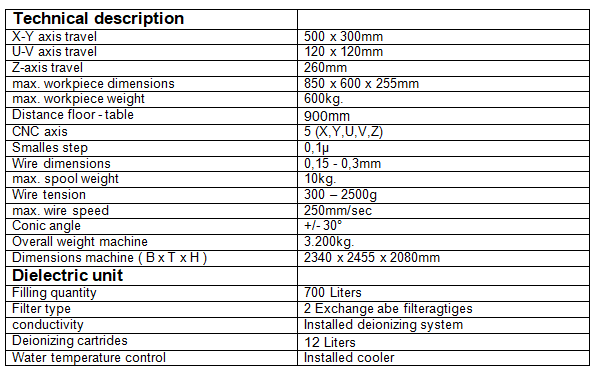

EDM WIRE-CUT MACHINE Model 500G

- Massivce ribbed casting for right precision

- Autom.levelling in working tank

- Working tank with front door

- Linear scale for X and Y axis

- 0,1 µ - step

- AWT-dry feed system in working gap

within 10 sec.

- Disposal of unused wires by compressed air

- Special corner control strategies

- Real Time Sparking RTS

- Freie-Elektolyse-Generator

- AWT – Diagnosis Screen

- 15 Zoll - LCD Touchscreen with Keyboard, Mouse

- Remote Control with Display

- USB, LAN , RS 232C - Interface

- Pentium 64 Bit 64 BIT High Speed CNC - controller

- Ethernetboard

- Standard-tooling set (for daily maintenance)

- Cooling unit incl. temperature control

CNC-control

Graphic XY - plane, XY - YZ - plane, 3D, graphics functions,

Edm display etc.

Software

Interpolation Linear, circle

Program name 8 alphanumeric Single bold

Program control function Graphics and simulation

Max. data size 512 MB

Manual data input (MDI) Standard

Maintenance information Wire consumption, raisin performance, cutter, dielectric

filter, lubrication, current supply

Datum Year, Month, Day

Edit function Insert/overwrite, mark (line, block, field), cutting and

pasting, search, replace, Undo/Redo etc.

Program bifurcation Call under-program, standard

Zoom-function 0,001- to 1000-times

Assistant Execute special program sequences by function keys

Program diagnosis Hint NC-Code-input error

Functions

Set coordinates Relative, Absolut, different points, vertical alignment

(auto/manual), conic data

coordinates memory Coordinates store and move towards coordinate

Insert function Edge function, center in slot, 3 points (manual),

start position edm, move to stored position, correction

of work piece position

Machine commands M-Codes, T-Codes, G-Codes

Data commands store, upload, delete, rename, new

Edit commands delete, insert/replace, mark, move, copy, cut out, search,

edit technology database

External data transfer Serial interface , serial outlet

Graphics function Define graphics display, record cutting way, Zoom, basis

display

Manual working MDI- Modus, JOG-Modus

NC-Programm Standard (Graphic, Graphic-NC Data simulate), Program

execution display, Display/active operating data during

machining; Possibility to interrupt program, execution of

MDI operations, restart program t breakpoint, process

parameter, Offset

Prozess control display Graphic display, Display suffix coordinates/free choose

coordinates, machines status report

Coordinatesystem-overall view Display distance from machine-datum; and from every

axis datum

NC-setting Process parameter, Offset

Setting Erosion Technologies parameter, Servo parameter, global Technology parameter

Setting communication Serial

USB functions Automatic Data load